With the hydraulic bender i find wrapping rag around the rollers helps alot with the dents in the top of the tube, 4-5 wraps then masking tap...

To do the reverse bend on them though the only way i have had success is doing one largish bend by marking the tube in 10cm increments taking up

the strain then pumping count your strokes, then move to the next mark do the same untill you have a nice wrinkle free bend (work your way out from center of bend), then, cut it in the midl flip one side around sleeve and plug weld it, when its straight and your happy with it you can then go ahead and weld the entire join. Flap disk the weld off and noby is the wiser

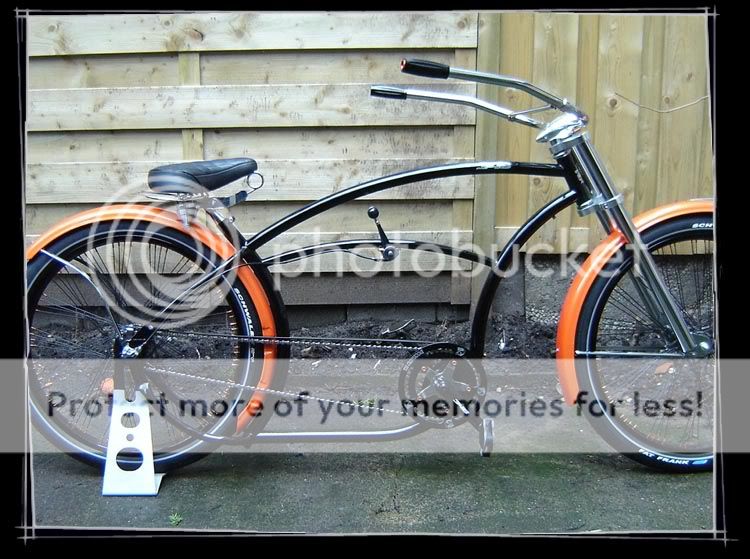

How i did my front tube...

RE: Endless Sphere haha yes there are some .... cluey fellas there, im not one of them, The non-hub motor section i suggested contains the pick of the bunch IMO

it is more technical than the hub motor section with gear ratios reduction drives and the like, if you want oooober easy Uncle, hub motor controller and throttle cant go wrong they all plug into one another nothing too learn at all..could have a hub motor fitted to any bike in under an hour eeeeasy without ever having read a word of instructions.

Look forward to seeing the new build mate, have we a design sketched or is it in the head?

KiM