You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Delta horn

- Thread starter El guapo

- Start date

Help Support Rat Rod Bikes Bicycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Fixable! As long as the inside isn't rusty, you should be able to get it going with the adjustment screw on the back. What I do is run the screw all the way in, put the horn wire directly to the battery (while in the cage), then slowly turn the adjustment screw out. If you have a third arm, this is much easier. Putting the wire straight to the battery eliminates the variable of the button being the part at fault.

You will be shocked when the horn suddenly sounds off. So don't do this atop a ladder. When you get a good, solid, consistent sound, you'll know it's good. Then put the wire back in the contact and try it from there. If nothing, then you know you've got a contact issue eslewhere. Sand off the wire end, both battery terminals, and the inside of the wire contact (this one's tricky).

Try again.

If nothing, then you can assume it's in the button. Most of these are pretty easily disassembled with little metal fingers you can just pull up. Make sure the spring and contacts inside are clean. May need to shim some more metal in there to assure it makes contact. Reassemble.

Try again.

Good luck!

You will be shocked when the horn suddenly sounds off. So don't do this atop a ladder. When you get a good, solid, consistent sound, you'll know it's good. Then put the wire back in the contact and try it from there. If nothing, then you know you've got a contact issue eslewhere. Sand off the wire end, both battery terminals, and the inside of the wire contact (this one's tricky).

Try again.

If nothing, then you can assume it's in the button. Most of these are pretty easily disassembled with little metal fingers you can just pull up. Make sure the spring and contacts inside are clean. May need to shim some more metal in there to assure it makes contact. Reassemble.

Try again.

Good luck!

Thanks for me as well.

That should be in the how to section

That should be in the how to section

That's a great description! :mrgreen: got mine working now

I used this method and got my handlebar Delta horn working fine.

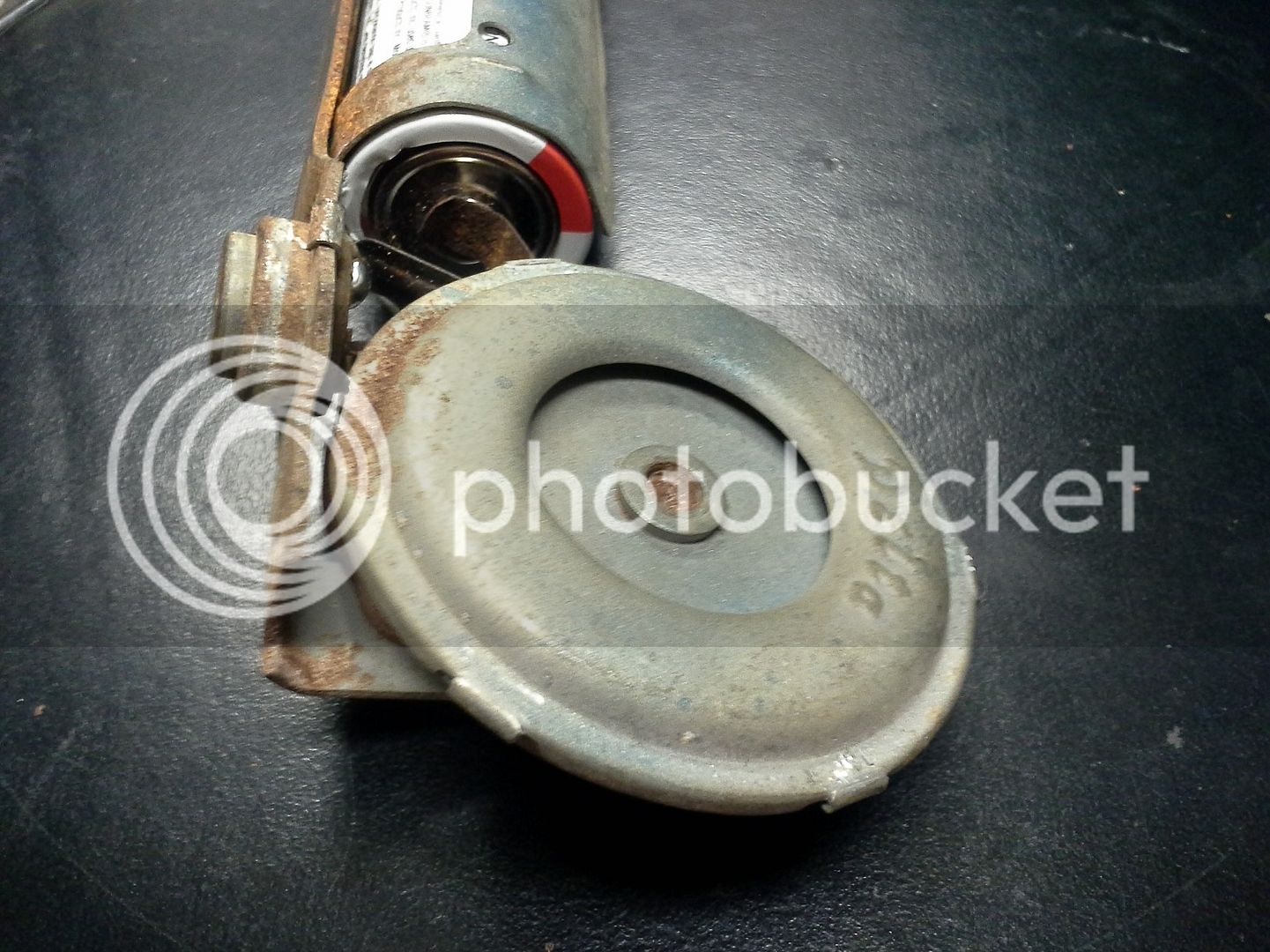

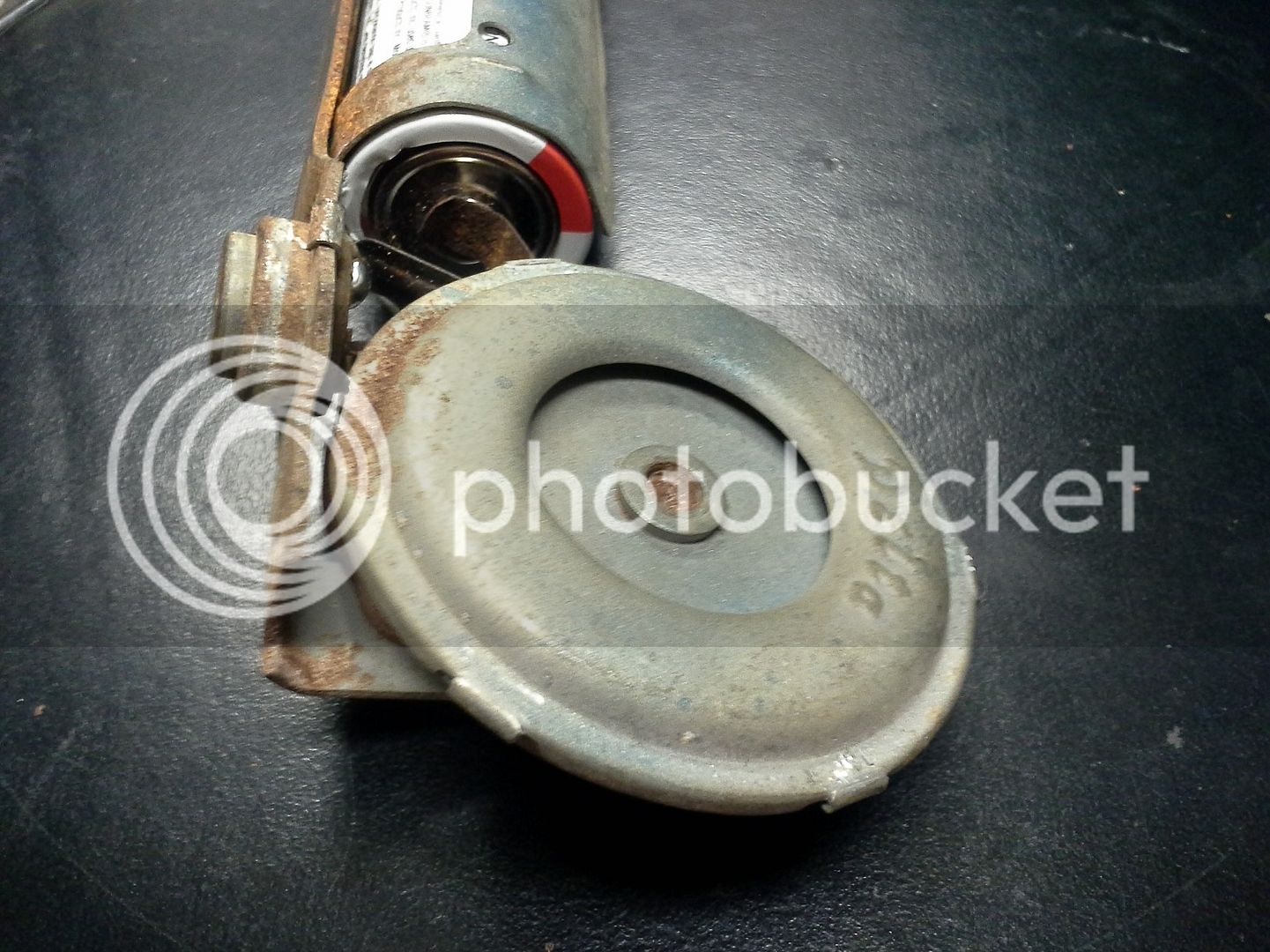

Then I started working on the Delta tank horn that came with the Columbia tank that I have for FireWing. I still don't have it working completely, but I took some disassembly photos and thought this would be a good place to share them for future reference.

Took the horn apart and started doing some continuity tests on various pieces after I sanded all of the contact points that I could think of.

I took apart the swtich and found that both of the rivets for the horn wire connector and the batter Positive side spring did not have any continuity with the connector or spring.

I didn't want redo the rivet, so I sanded everything up and loaded up some solder to make the connection on viable again.

Here is an exploded view of the switch and the assembly order

Took the horn apart and started doing some continuity tests on various pieces after I sanded all of the contact points that I could think of.

I took apart the swtich and found that both of the rivets for the horn wire connector and the batter Positive side spring did not have any continuity with the connector or spring.

I didn't want redo the rivet, so I sanded everything up and loaded up some solder to make the connection on viable again.

Here is an exploded view of the switch and the assembly order

Here is an exploded look at the inside of the horn itself.

I cleaned up the caonnections and had tweak the way the conact adjustment arm was bent in order for the contacts to connect when voltage was applied.

After that I placed the middle horn piece back in and applied power and could get it to rattle.

Then I put the outer shroud back on and pinched the tabs back down.

I think maybe there is a magic formula as to how tight these tabs need to be, because I can only get it to make a muffled horn sound now.

So there is my documentation on how to partially make a delta tank horn work.

Has anyone else been successful in putting the horn section back to together?

Any tips on what I may have done wrong?

I cleaned up the caonnections and had tweak the way the conact adjustment arm was bent in order for the contacts to connect when voltage was applied.

After that I placed the middle horn piece back in and applied power and could get it to rattle.

Then I put the outer shroud back on and pinched the tabs back down.

I think maybe there is a magic formula as to how tight these tabs need to be, because I can only get it to make a muffled horn sound now.

So there is my documentation on how to partially make a delta tank horn work.

Has anyone else been successful in putting the horn section back to together?

Any tips on what I may have done wrong?

Kingfish, The final assembly of the horn button looks like some solder on the spring clip is touching the case tab folded over the disc. Looks like that disc is an insulator and can not have continuity to the case. Other than that,test battery voltage during operation.Do the batteries go in the other direction? When that disc is drawn to the electromagnet it hits a reed switch. I found that operation inproved with a spritz of WD40 into the hole for the tone adjustment screw.

Thanks for the input. I double checked and no solder is hitting that tab.

Voltage good. Electromagnet engages when button is pushed. Batteries are in correctly.

The emag pulls the center down and it hits that reed switch.

I tried the wd40 trick, but it is still a very muffled sound no matter where I adjust the screw at.

Voltage good. Electromagnet engages when button is pushed. Batteries are in correctly.

The emag pulls the center down and it hits that reed switch.

I tried the wd40 trick, but it is still a very muffled sound no matter where I adjust the screw at.

Didn't get it to sound like I wanted, so I replace the horn unit with one of my Royce ones. Works like a champ!