polishing the chanel

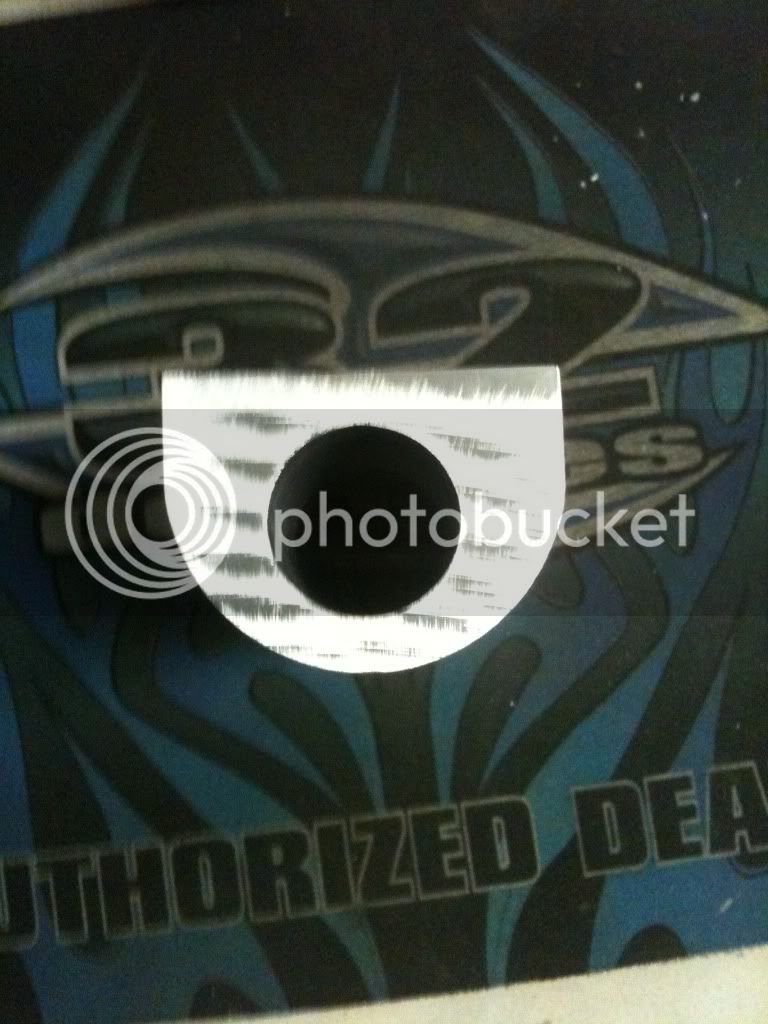

and this it is the final product

I hope you guys enjoy my work and you like what I do hire

I will start to buildthem next week

valy said:I hope you like this one better

here is another tube notcher

here is another tube notcher

valy said:hello hondataeh6 it is not a fix dimension you can have any dimension what you wish .

but if you like mine plates they are 200mm x 70,5mm x 15mm and 240mm x 60mm x 12mm

sorry I wos late with ansure.

Enter your email address to join: