- Joined

- May 5, 2016

- Messages

- 218

- Reaction score

- 345

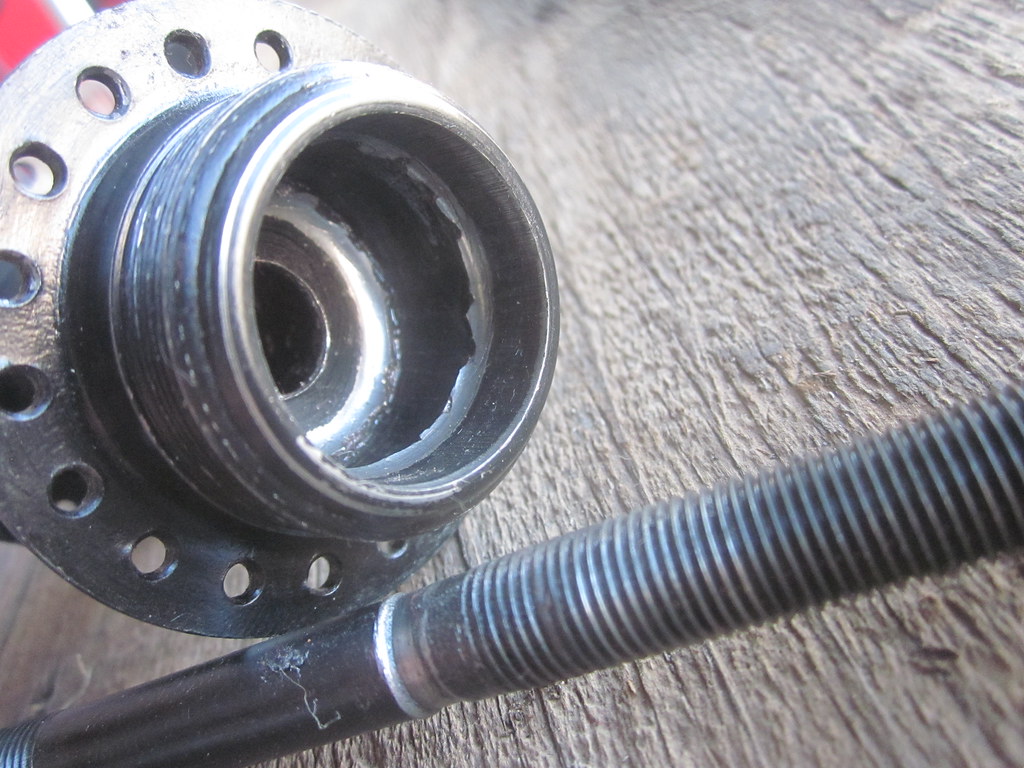

has anyone else ever had a Loose bearing cup in a wheel hub- i had not

and it was making a heck-uva racket, an I could not get the bearings adjusted to save my life

The cup was spinning freely in the hub, so i took it out, and first tried grinding divots around (the surprisingly hard) cup exterior, to raise a burr, but no luck

so i used my 110 fcaw welder, clamped the cup in the ground, pressed the trigger and let go, then touched the wire to the cup exterior.

a tiny spark and a tiny bump. time like 25 all around the out side, then a quick file, then it fit(forgot to take pictures of these "cold welds"

but it worked, no more slippage

and it was making a heck-uva racket, an I could not get the bearings adjusted to save my life

The cup was spinning freely in the hub, so i took it out, and first tried grinding divots around (the surprisingly hard) cup exterior, to raise a burr, but no luck

so i used my 110 fcaw welder, clamped the cup in the ground, pressed the trigger and let go, then touched the wire to the cup exterior.

a tiny spark and a tiny bump. time like 25 all around the out side, then a quick file, then it fit(forgot to take pictures of these "cold welds"

but it worked, no more slippage