So I got this a few years ago for almost nothing at an outdoor furniture store. Old trikes don't cost much as it is right now, which was a little surprising to me considering rusty old pedal cars are being listed for (not sold I'm pretty sure) stupid money on eBay. Anyhoo, it's time to take it apart and redo it for the little one. Not have too much luck sourcing parts yet. Don't need to be original but should fit without too much difficulty. Anyone have some good trike parts sources? :wink: :lol:

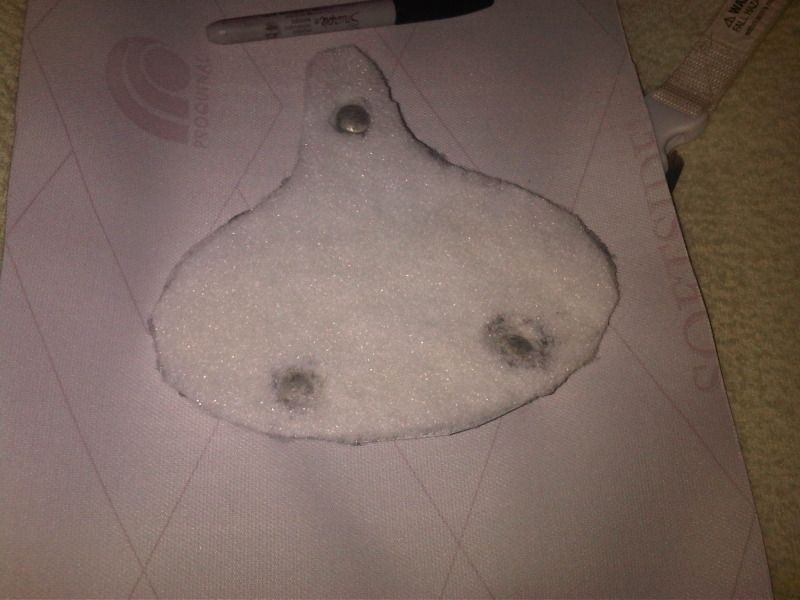

I sprayed all the bolts last night so hopefully too much doesn't get broken in the teardown. Would rather do new air tube tires front and rear than dealing with the hard rubber stuff. The bars, frame, and seat will be reused, not sure if the fenders can be cleaned up enough. Thinking of metallic lime green powder coating the frame and gloss black for everything else, light tan leather for the seat and grips. Don't want to get ahead of myself yet though.

I sprayed all the bolts last night so hopefully too much doesn't get broken in the teardown. Would rather do new air tube tires front and rear than dealing with the hard rubber stuff. The bars, frame, and seat will be reused, not sure if the fenders can be cleaned up enough. Thinking of metallic lime green powder coating the frame and gloss black for everything else, light tan leather for the seat and grips. Don't want to get ahead of myself yet though.