I ordered an 80cc kit for my other chopper build, and decided it was way too small. So while i wait on parts for it, i need something to keep me busy..

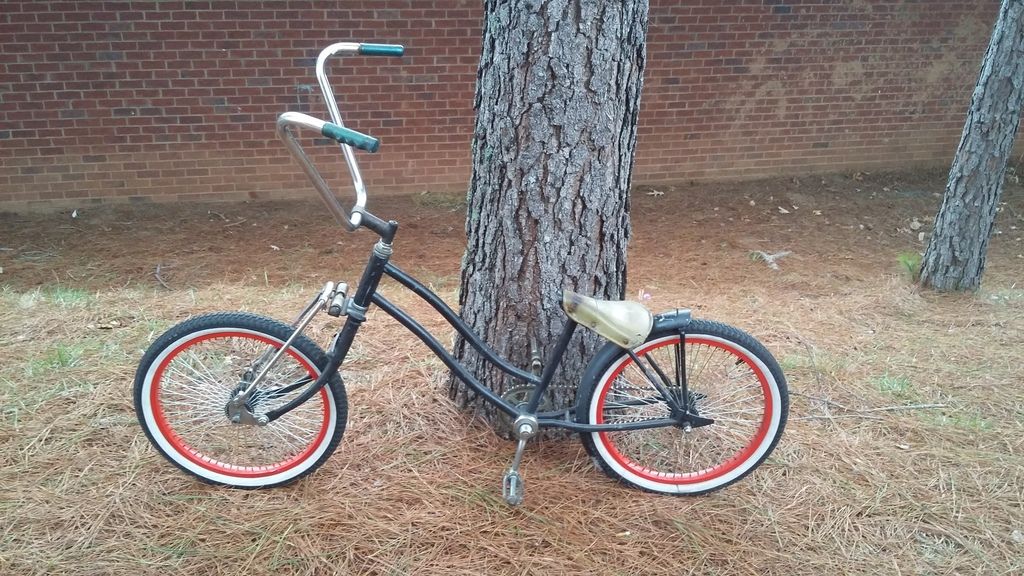

Sooo, i have this Sears 20" girls frame, that has a 26" starliner rat trap springer forks, with reversed knuckles.... 80 spoke straight laced wheels from freestyle bike, white walls from a donor girls bike, orginal sears handle bars, and space liner seat.

And this 80cc kit.

And a Lincoln mig welder.

So this:

Plus this:

With a little bit of this:

Stay tuned for the venture and end result.

Sooo, i have this Sears 20" girls frame, that has a 26" starliner rat trap springer forks, with reversed knuckles.... 80 spoke straight laced wheels from freestyle bike, white walls from a donor girls bike, orginal sears handle bars, and space liner seat.

And this 80cc kit.

And a Lincoln mig welder.

So this:

Plus this:

With a little bit of this:

Stay tuned for the venture and end result.