Re: Bare Minimum.

thanks for taking the time to post the overhaul. Interesting.

thanks for taking the time to post the overhaul. Interesting.

Craiggo said:...and what I am really excited about. p.s. this idea was stolen from Dr. Tankenstein. Thanks!

the post clamp isnt contacting like it should but It seems to be pretty rigid anyway. I will see if this poses any problems once I can actually put weight on it.

Im not sure exactly how I will be able to secure it to the bike yet. I might end up bending the "bottom" crank arm straight down using a heating torch. what do you guys think?

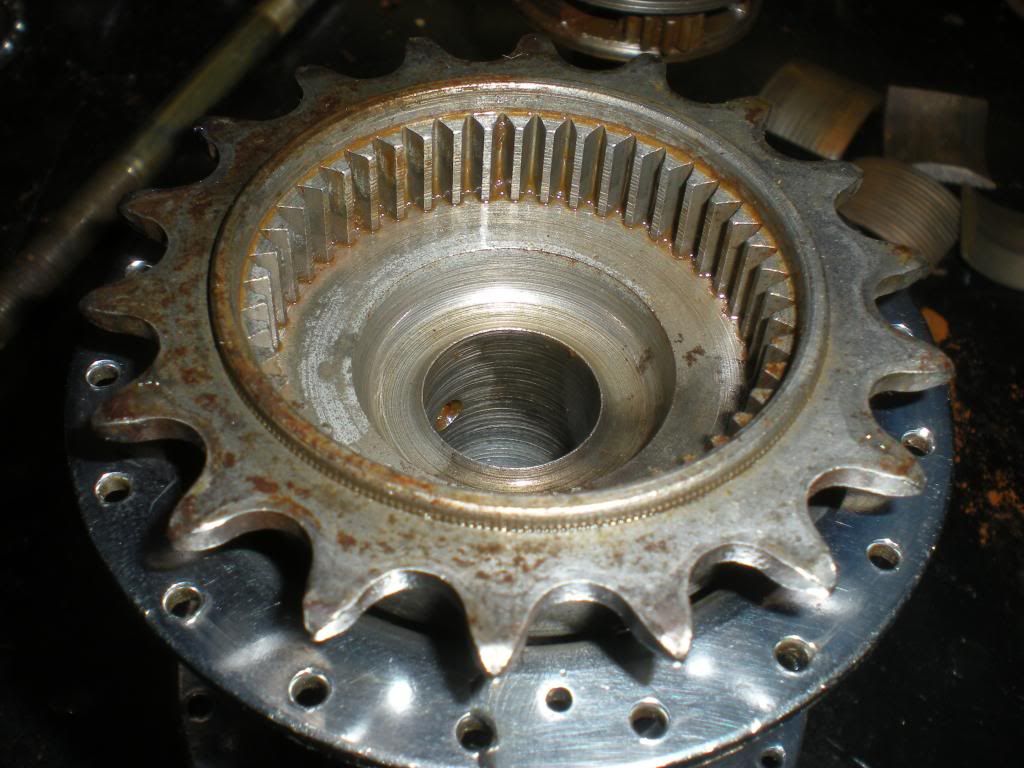

I meant that as a compliment. I had a kick back that I was to scared, so I had the LBS rebuild it for me.Craiggo said:I guess the way I look at it is, I would rather put 5 or so hours into something like that hub rather than buy a different one.

IronDio said:That is really cool! I have a crank off an old Columbia that was run over, so one side is bent...that would be a great way to recycle it! Great build thread! I'm watching this one closely from here out!

deorman said:Are you going to be able to put the crank into the post on the seat side? You could always shorten the arm a bit. Good eye for the aesthetics of the "moto" genre. Good thing, 'cause given the bike's condition, a "performance" build would probably kill that frame. Good save on the hub, and not a minute too soon. 8)

cman said:I meant that as a compliment. I had a kick back that I was to scared, so I had the LBS rebuild it for me.Craiggo said:I guess the way I look at it is, I would rather put 5 or so hours into something like that hub rather than buy a different one.

Sent from my ADR6425LVW using Tapatalk 2

Can you explain the magnesium? I'm not sure what you mean. Thank you, and all the others for the praise I am getting! It is really appreciatedCCR said:ever think of sticking a piece of magnesium on the bottom of that rear fender ? Awesome stuff so far man, big pat on the back for saving that hub too :shock: seat post looks awesome, its like seeing a pipe and fitting contraption but way cooler !!!

LukeTheJoker said:I may be wrong, but I think he means to use it as a sparker as you ride along... The magnesium would spark as it scrapes along the road.

Like I said though, I may be wrong...

Luke.

deorman said:I would say split tubing welded, but you need it to bent to match the bend in the stay. Even if you manage, I wouldn't be hopping cubs with it. It's pretty far gone. Once you open a tube like that, it oxidizes like crazy.

Enter your email address to join: