I am starting another fork for my Beast. This one is going to be way different from the first. First off its going to be make with a lot more aluminum, plus its going to have a lot more travel, and I am using a way better shock. I need to find a place to get bearings that won't break the bank.

Yesterday i got the aluminum. 6061t6 to be exact. The legs and links will be made from 1"x2" solid bar. Once the basic shape is done, ill mill out all the excess material to make them lighter. I got 8 feet of this stuff!

Then I found a chunk of 6061t6 that is 6"x6"x2". this will become the upper and lower crowns. Ive got some cool ideas for offset crowns!

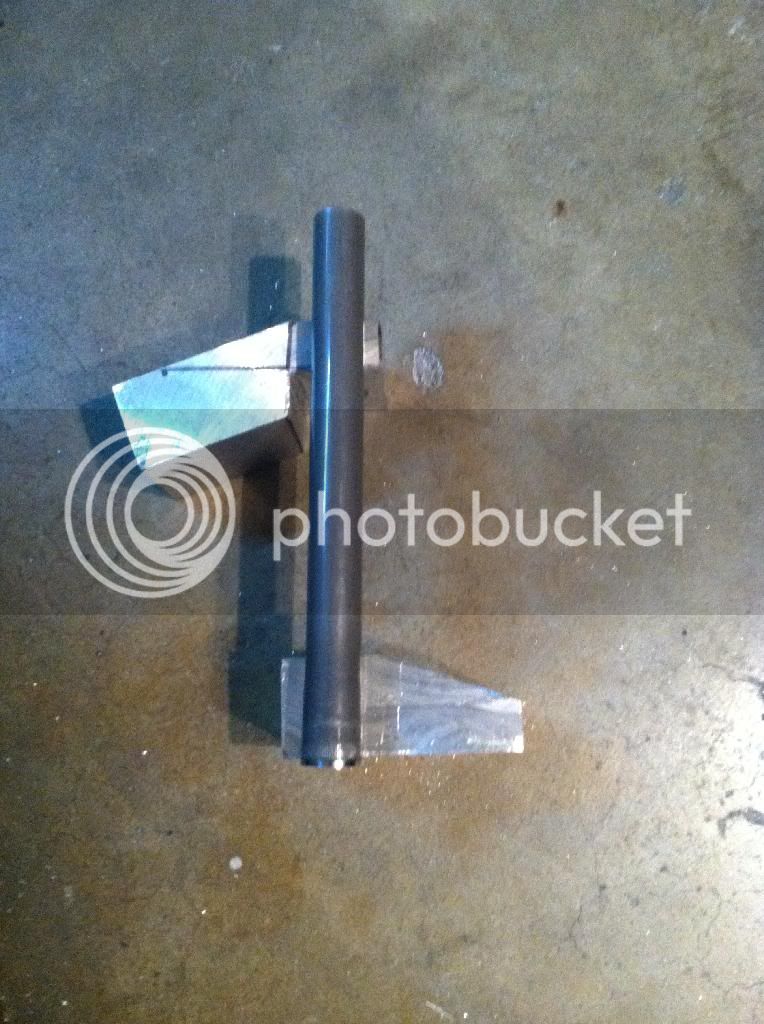

Here is the shock. Its a Fox Float R with adjustable compression and pro pedal. Its 8 1/2 inches long with 2 1/2 inches of stroke. I got it a couple weeks ago, used for a real good price:

I have learned a ton about linkage forks since the first one I made, this fork should be WAAAAAAY better than the last, as long as I don't screw it up while making it! I am hoping for 6 1/2 to 8 inches of travel. The links will be different lengths, so that I can play with the axle path more. Hopefully the axle path will be slightly curved, with the initial travel pulling the wheel back so that I don't get brake dive. Also the crowns will be offset from the steerer tube so that the trail and rake of the fork will be better. Its going to take me a lot longer to make this one than the last because of all the milling ill have to do, but the results will be worth it!

Yesterday i got the aluminum. 6061t6 to be exact. The legs and links will be made from 1"x2" solid bar. Once the basic shape is done, ill mill out all the excess material to make them lighter. I got 8 feet of this stuff!

Then I found a chunk of 6061t6 that is 6"x6"x2". this will become the upper and lower crowns. Ive got some cool ideas for offset crowns!

Here is the shock. Its a Fox Float R with adjustable compression and pro pedal. Its 8 1/2 inches long with 2 1/2 inches of stroke. I got it a couple weeks ago, used for a real good price:

I have learned a ton about linkage forks since the first one I made, this fork should be WAAAAAAY better than the last, as long as I don't screw it up while making it! I am hoping for 6 1/2 to 8 inches of travel. The links will be different lengths, so that I can play with the axle path more. Hopefully the axle path will be slightly curved, with the initial travel pulling the wheel back so that I don't get brake dive. Also the crowns will be offset from the steerer tube so that the trail and rake of the fork will be better. Its going to take me a lot longer to make this one than the last because of all the milling ill have to do, but the results will be worth it!