Hello again, everyone!

Here i start another build thread. There are quite a lot of projects i am working on at same time, i realize that, but it is very hard to hold myself from working on each of them since they all are awesome and attractive in their own way

I liked the way 346 Basman looks since i first saw it in 2013 while buying my first cruiser bike from The Chopperdome, Amsterdam. But they were always too expensive for me, so i have never built one until now, though i always wanted to (secretly )

)

Anyway, when Ruff built a aluminium version of that frame i got hooked. After looking at them and collecting feedback i have finally purchased one, that is being my first ever frame i bought new from the shop (second if complete bike i bought in 2013 counts).

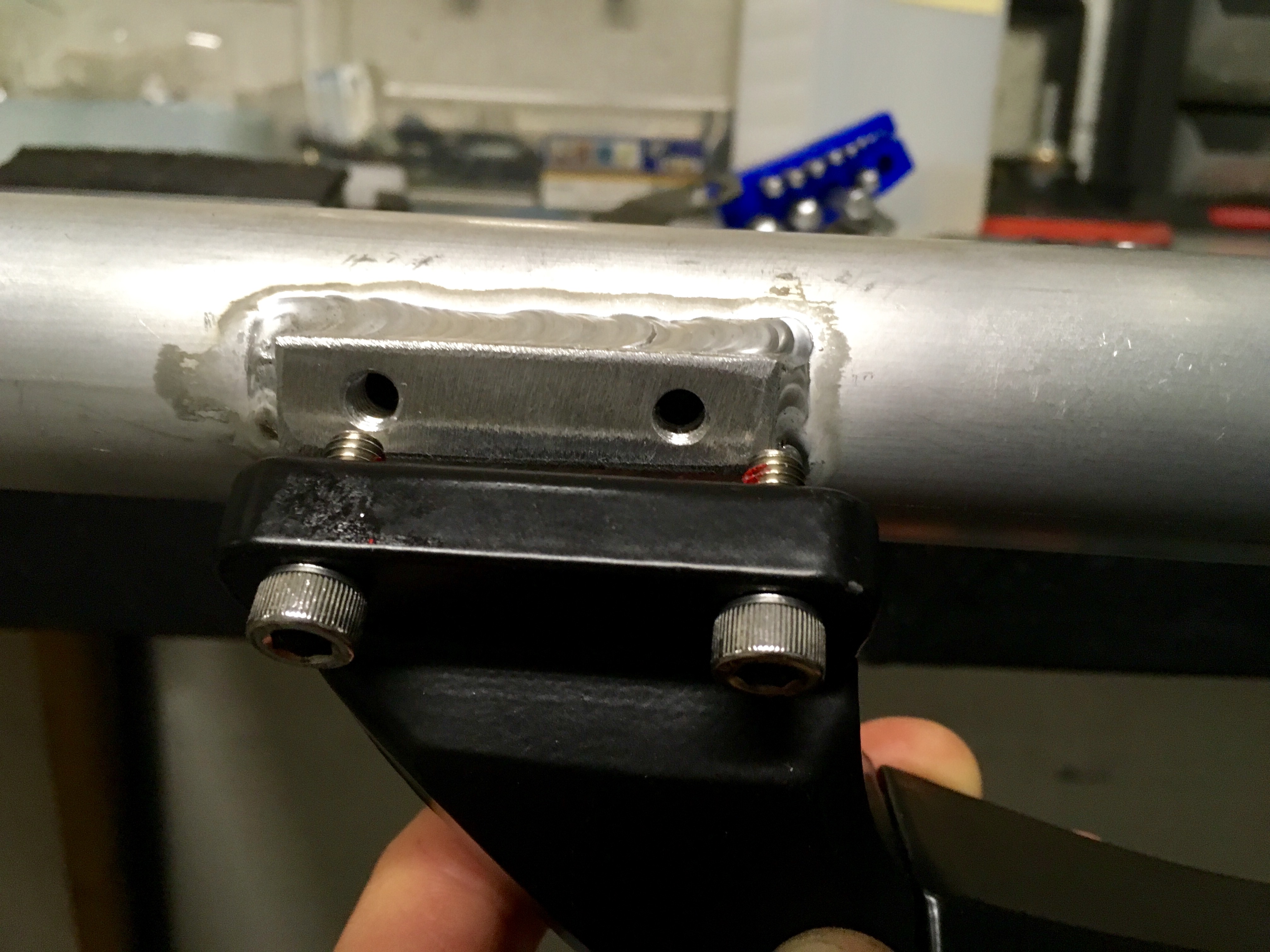

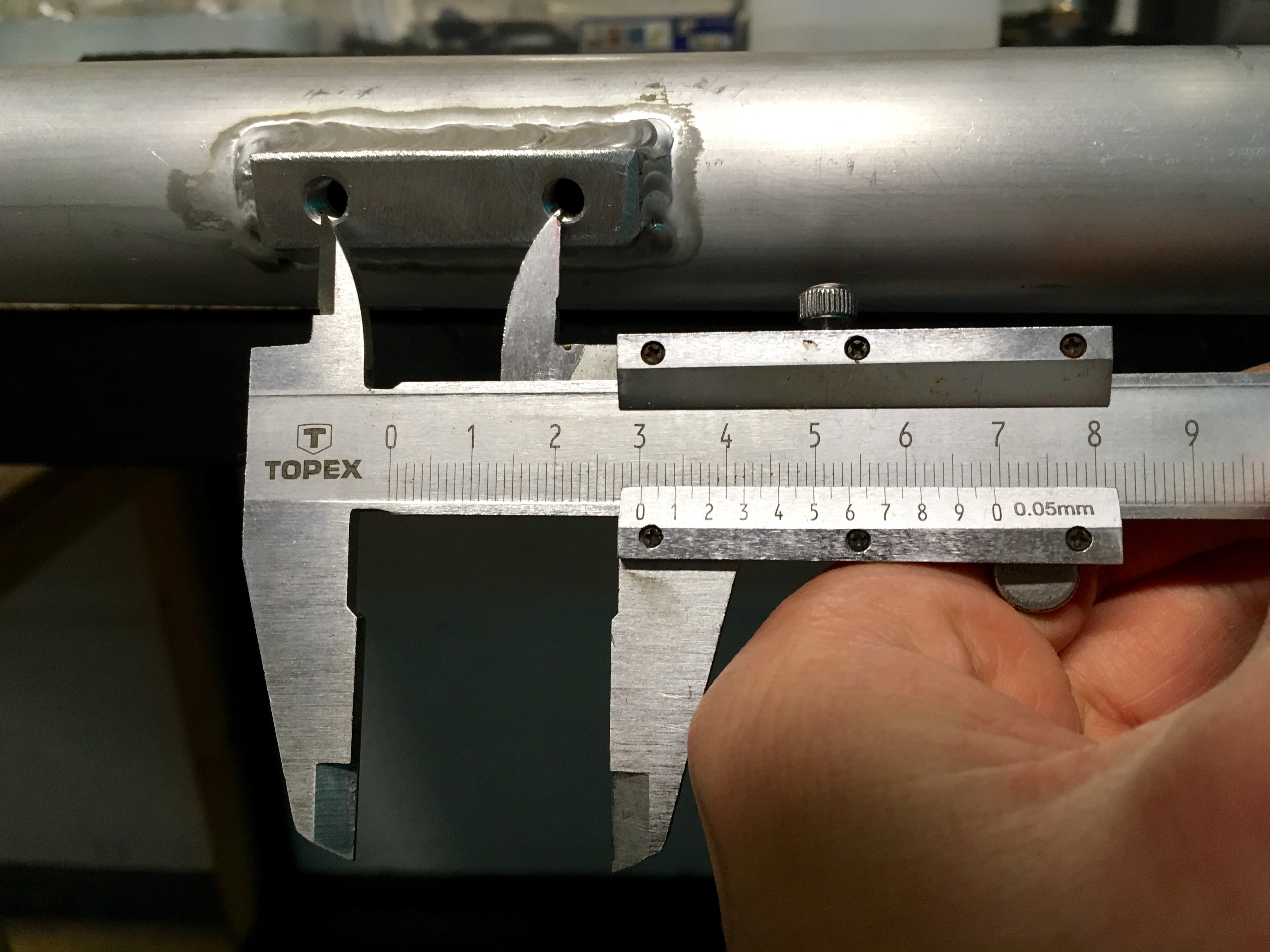

I have heard a lot of controversial things about it not being strong and reliable enough, and hey, surprisingly, looks like i got a new version of it, with extra plate reinforcing the bottom bracket.

Another reason for me to risk it was the fact that Ruff gives lifetime warranty for their bikes, so even if it cracks in the end i still may get a refund or something. I am still willing to hear any comments from folks who own this frame.

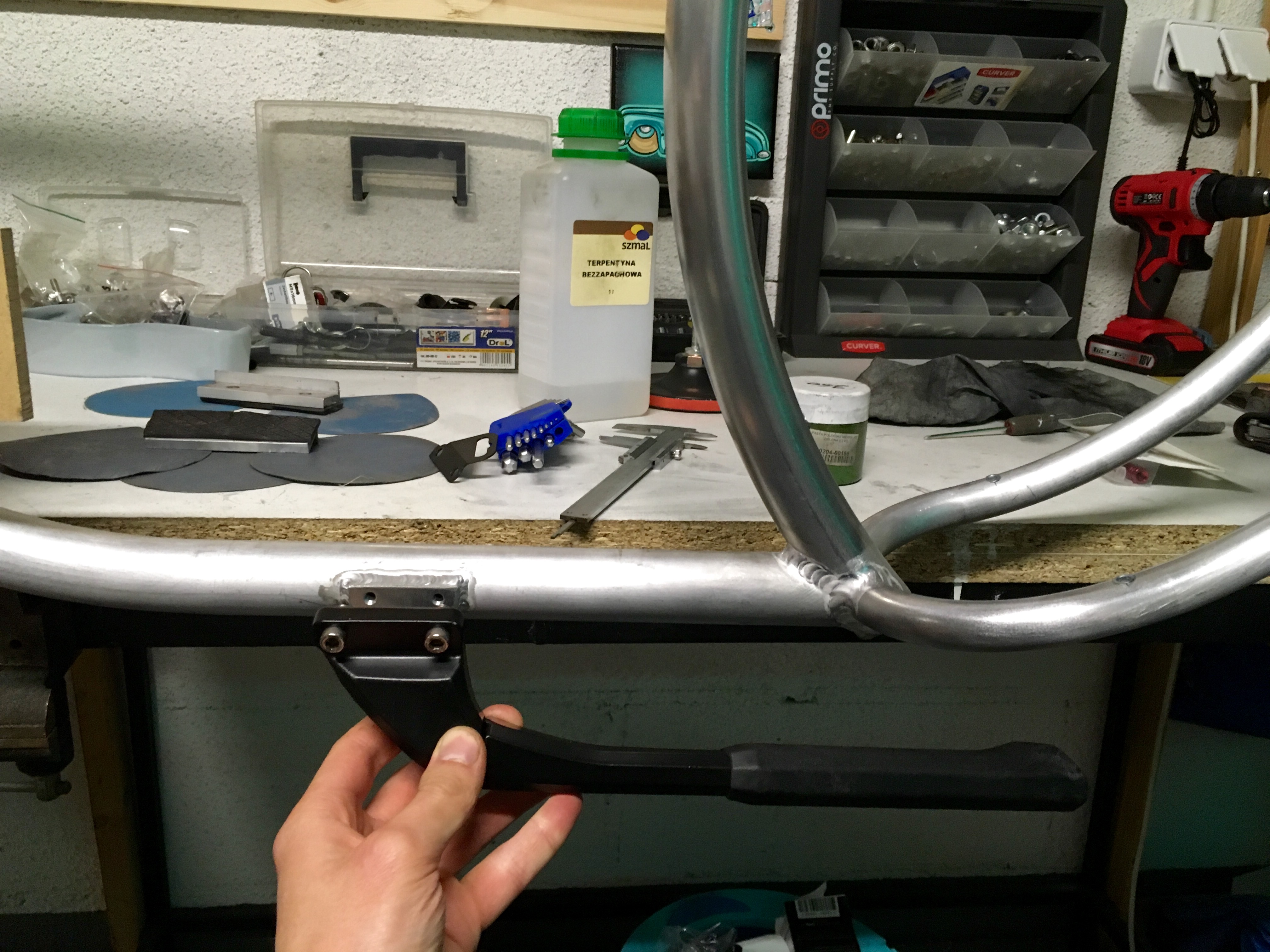

The idea for this build is simple: if it won't rust it does not need any paint. My plan is to polish the frame up to make it shiny, that's where this "Silver Bullet" is coming from, though the name could still change. The other thing: the frame is light. So i may use this quality too, trying to build the lightest bike of all i have. If i can keep it under 15kg i try to do that, more then possible i think. The heaviest part i am going to use would be Shimano Nexus 8 hub, i love the gear width of 307% too much, and i love the coaster brakes on my bikes. Probably using about 50mm wide single wall rim for the back with boa-g tire, and some lightweight sport bike front wheel, 26 or 28 inch, possibly with thickslick tire. And some lightweight sport bike aluminium fork. Same goes for cranks, light and sporty.

So we will see where it goes, by now i am only starting with the frame.

Here i start another build thread. There are quite a lot of projects i am working on at same time, i realize that, but it is very hard to hold myself from working on each of them since they all are awesome and attractive in their own way

I liked the way 346 Basman looks since i first saw it in 2013 while buying my first cruiser bike from The Chopperdome, Amsterdam. But they were always too expensive for me, so i have never built one until now, though i always wanted to (secretly

Anyway, when Ruff built a aluminium version of that frame i got hooked. After looking at them and collecting feedback i have finally purchased one, that is being my first ever frame i bought new from the shop (second if complete bike i bought in 2013 counts).

I have heard a lot of controversial things about it not being strong and reliable enough, and hey, surprisingly, looks like i got a new version of it, with extra plate reinforcing the bottom bracket.

Another reason for me to risk it was the fact that Ruff gives lifetime warranty for their bikes, so even if it cracks in the end i still may get a refund or something. I am still willing to hear any comments from folks who own this frame.

The idea for this build is simple: if it won't rust it does not need any paint. My plan is to polish the frame up to make it shiny, that's where this "Silver Bullet" is coming from, though the name could still change. The other thing: the frame is light. So i may use this quality too, trying to build the lightest bike of all i have. If i can keep it under 15kg i try to do that, more then possible i think. The heaviest part i am going to use would be Shimano Nexus 8 hub, i love the gear width of 307% too much, and i love the coaster brakes on my bikes. Probably using about 50mm wide single wall rim for the back with boa-g tire, and some lightweight sport bike front wheel, 26 or 28 inch, possibly with thickslick tire. And some lightweight sport bike aluminium fork. Same goes for cranks, light and sporty.

So we will see where it goes, by now i am only starting with the frame.