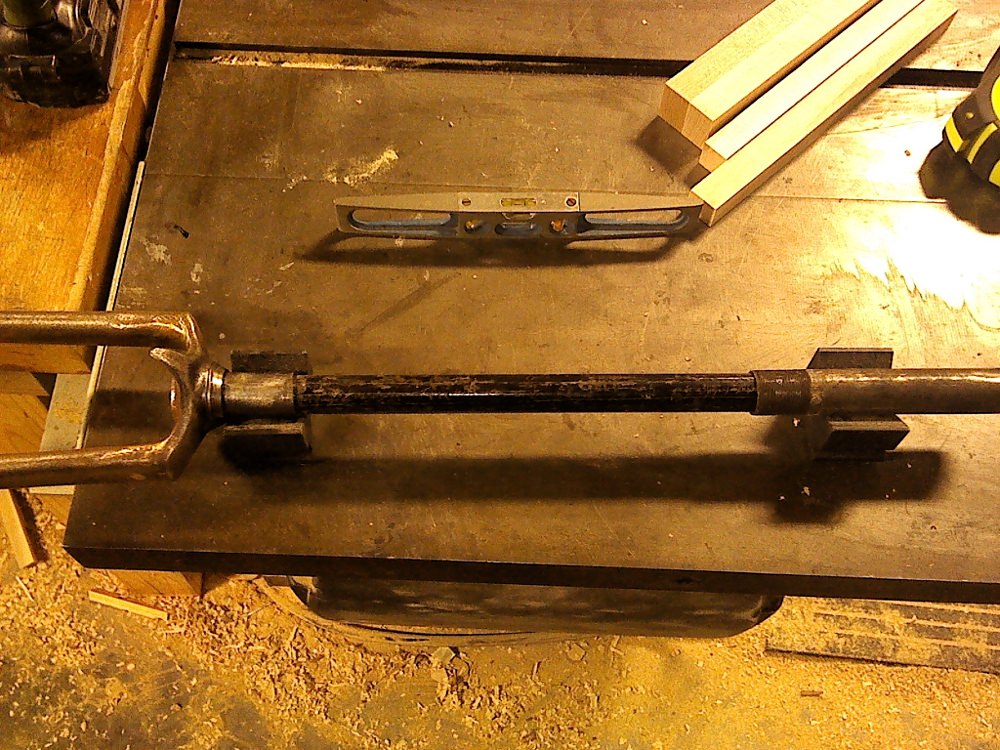

This build didn't get finished for BO12. To top it off photobucket ate my photos, so I had to deal with re-uploading them all. With a little luck I can get it finished this time. This is where I left off.

Last edited: