CHAMPION123 said:

Just a thought. I would go to a semi-trailer repair shop or find a good welder in your area that can weld aluminum. I don't know if J.B. weld would handle the stress very well. Or check with the local Harley Davidson shop. They know where all the good welders are located. Gary

Like I said, there are many issues with welding this part.

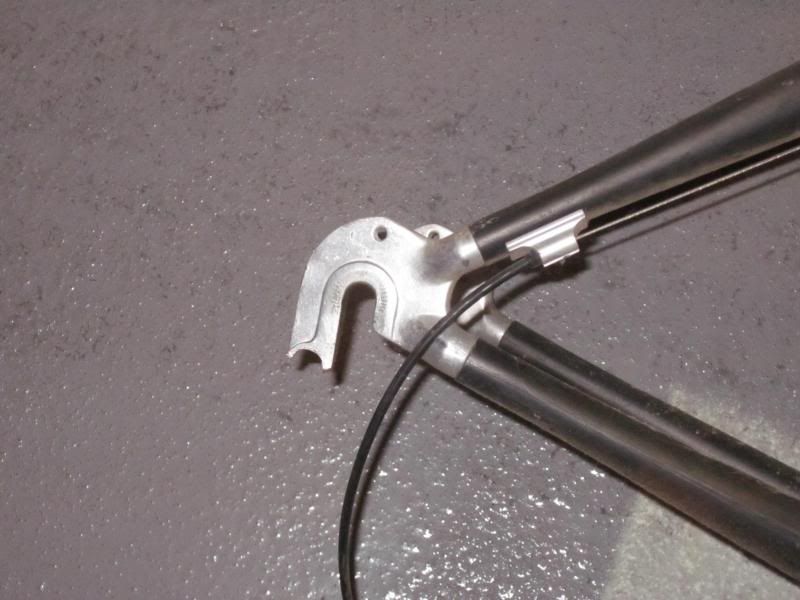

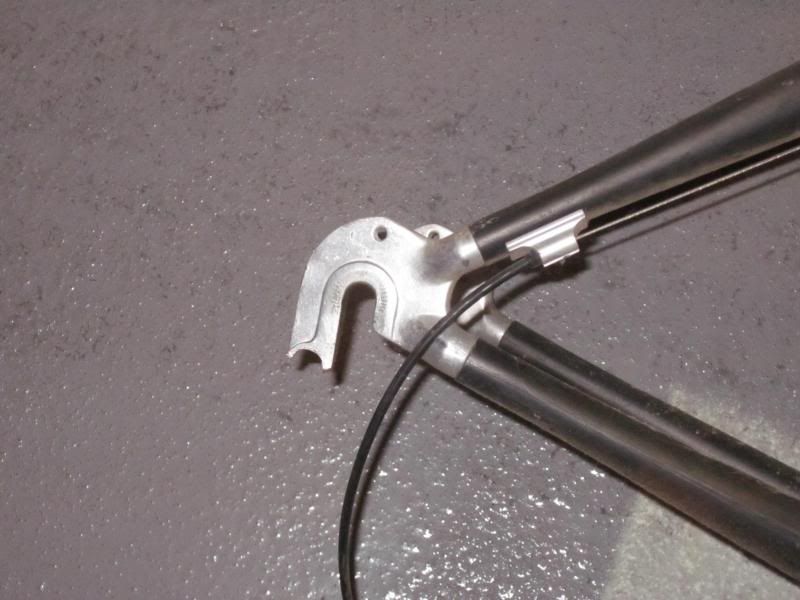

Welding on a small piece of aluminum that is bonded to carbon fibre with thermo epoxy that sets at just 150 degrees F isn't going to work. The outer surface of aluminum (aluminum oxide) melts at 3500+ degrees, the base aluminum melts at 1200 degrees. Aluminum is good at quickly transfers heat so keeping the heat away from the epoxy just an inch or two away would be a problem. Once welded, the aluminum surely needs to be heat treated (just like most aluminum bikes) at temps in the 300-400 F range to relieve the built up stresses that welding causes. The carbon frame would melt down for sure. Trek carbon frames are not "1-piece". They are built up from a number of molded carbon sections that are bonded together with a heat set epoxy.

There are many thousands of aluminum alloys. Usually identified by a 4 digit number that specs the percentages of the various other elements mixed in. 6061 & 7005 are a couple of the more common families of alloys used in bicycle frames. When you weld aluminum, you use a filler material designed for each specific base alloy. I have no idea what alloy Trek spec'd in the dropouts that were never intended to be welded, perhaps they chose a "non-weldable" alloy or a "non-heat treatable" mix for ease of manufacturing or for more strength. The part looks cast or perhaps it was forged (stamped) prior to machining. There is a whole different family of aluminum alloys meant for casting.

When I hear a welder tell me he can weld anything (including bikes that were never welded together in the first place), that reaffirms to me he is clueless about the metallurgy needed to do a reliable repair and the load stresses that bike frames are subject too. If he says "all aluminum is the same" run, don't walk, away.

I did some aluminum welding in my welding training and I was amazed at how easy my great looking welds snapped right off during testing. Welded aluminum gets much of its strength from the geometric shapes in the design of the product and proper heat treating during and/or after the welding. Round tubes and triangles as used in typical bicycle frames are far stronger than trying to butt weld flat plates which is what this repair would be.

I would bet any weld repair would fail very quickly on this part.