I'm looking at a couple of potential build projects and at the out of the box sprocket clamp / spoke hub assembly and wondering if anyone has uses a flip flop hub instead?

Flip flop hub with a freewheel on one side, a large fixed sprocket on the other would be ideal.. Just not sure if you can get big sprockets that fit the standard fixie hub threads.

Thoughts?

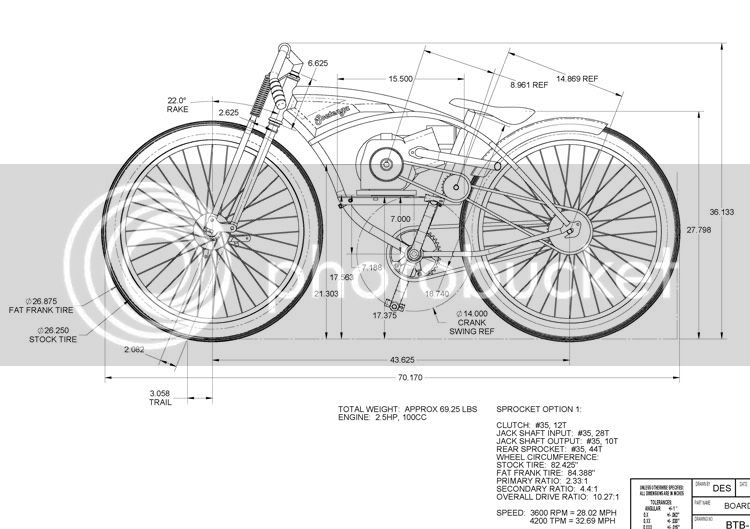

Just for fun, here are the two bikes I'm looking at motorizing:

K

Flip flop hub with a freewheel on one side, a large fixed sprocket on the other would be ideal.. Just not sure if you can get big sprockets that fit the standard fixie hub threads.

Thoughts?

Just for fun, here are the two bikes I'm looking at motorizing:

K