- Joined

- May 10, 2016

- Messages

- 1,446

- Reaction score

- 3,542

Man this is so awesome!

Inspiration for sure. I hope to weld a frame someday.

Lookin rad man!

Inspiration for sure. I hope to weld a frame someday.

Lookin rad man!

Man this is so awesome!

Inspiration for sure. I hope to weld a frame someday.

Lookin rad man!

Non Goose project by Paul de Valera, on Flickr

Non Goose project by Paul de Valera, on Flickr Non Goose project by Paul de Valera, on Flickr

Non Goose project by Paul de Valera, on Flickr Non Goose project by Paul de Valera, on Flickr

Non Goose project by Paul de Valera, on Flickr Non Goose project by Paul de Valera, on Flickr

Non Goose project by Paul de Valera, on Flickr

Non Goose project by Paul de Valera, on Flickr

Non Goose project by Paul de Valera, on Flickr Non Goose project by Paul de Valera, on Flickr

Non Goose project by Paul de Valera, on Flickr

) or, more likely from one of two old guys that fixed bikes in their garages for retirement income.

) or, more likely from one of two old guys that fixed bikes in their garages for retirement income.

I remember getting my "BMX" parts from thrifty ice cream..

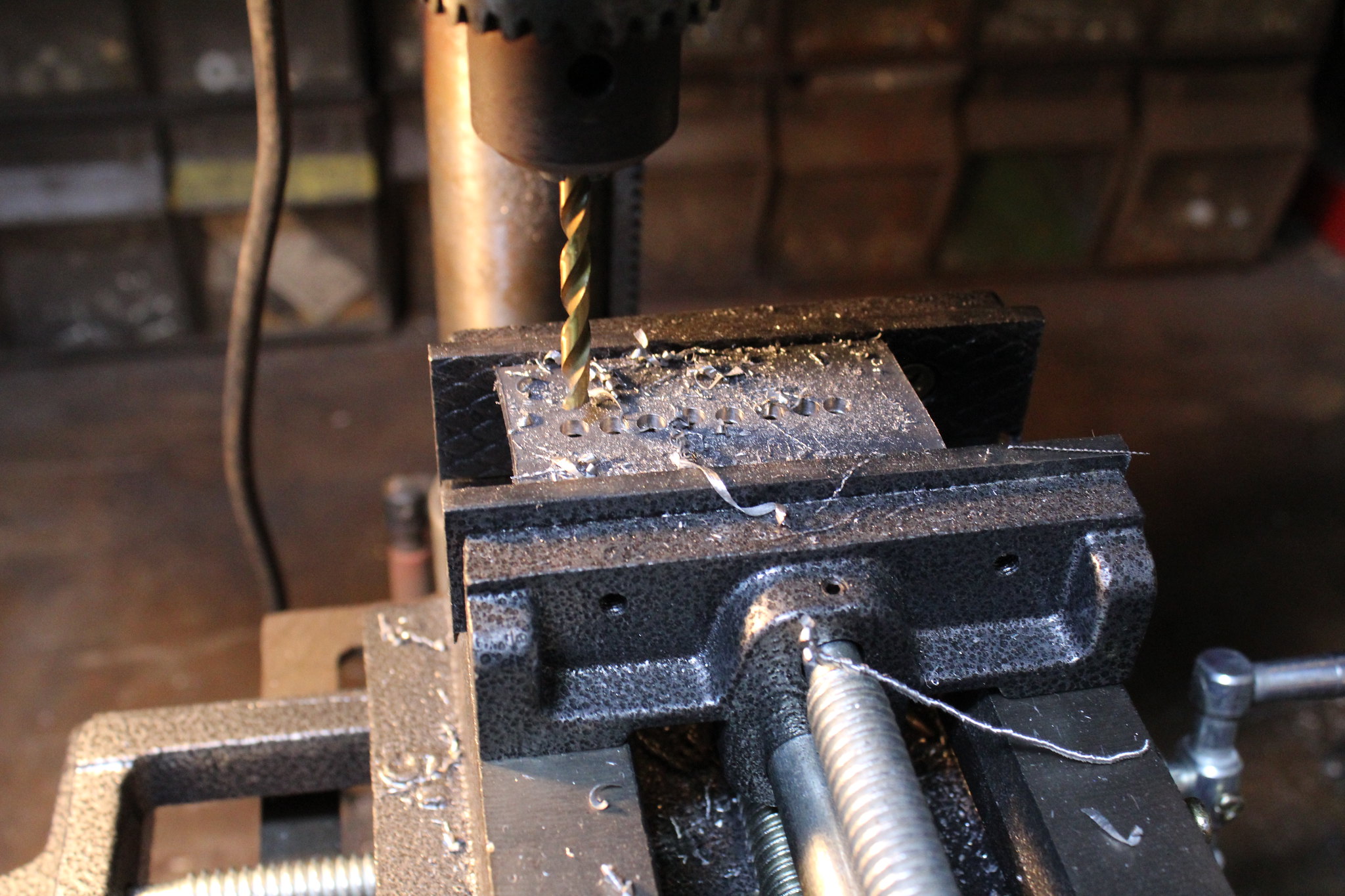

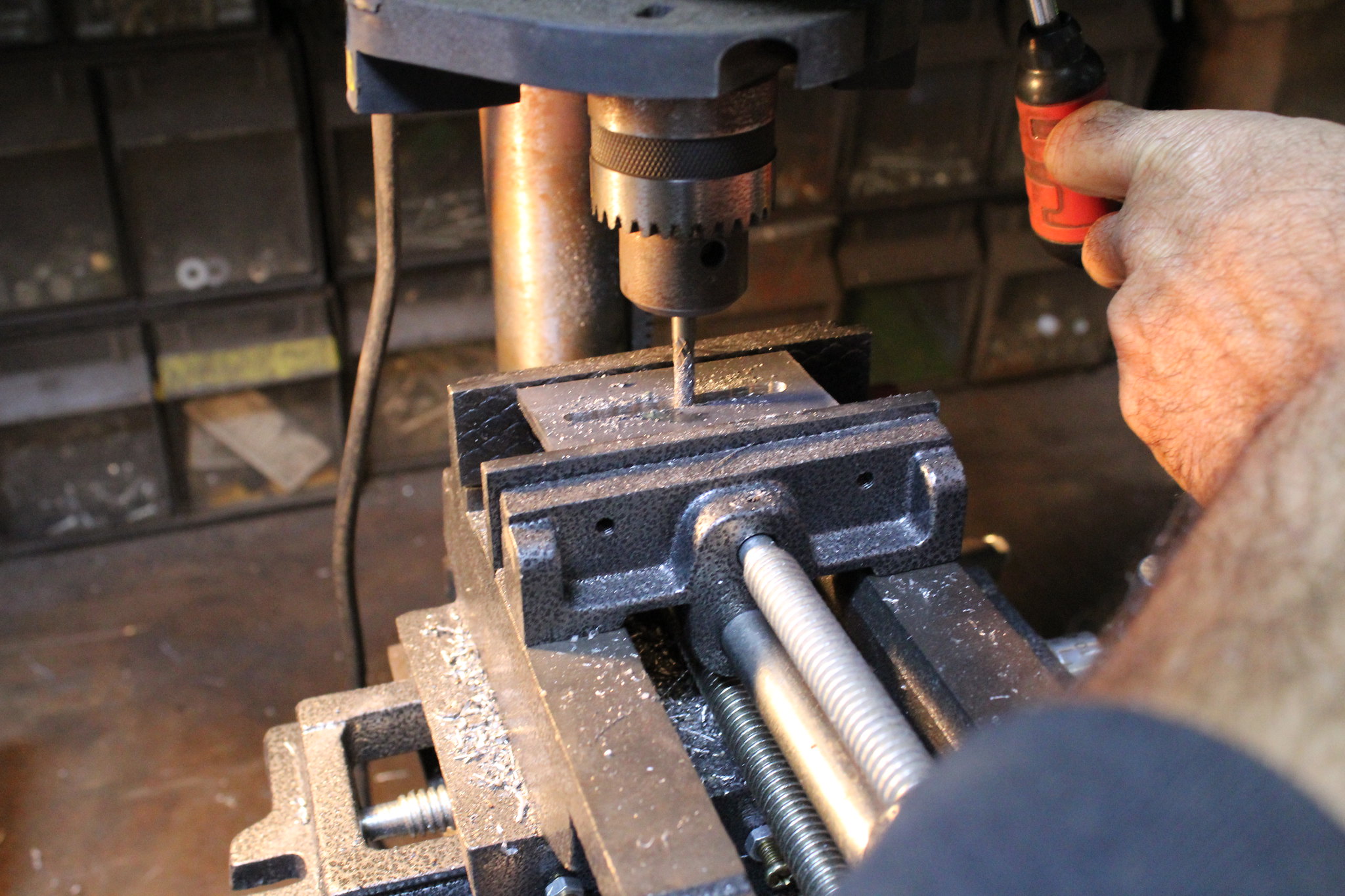

non goose project by Paul de Valera, on Flickr

non goose project by Paul de Valera, on Flickr non goose project by Paul de Valera, on Flickr

non goose project by Paul de Valera, on Flickr non goose project by Paul de Valera, on Flickr

non goose project by Paul de Valera, on Flickr non goose project by Paul de Valera, on Flickr

non goose project by Paul de Valera, on Flickr non goose project by Paul de Valera, on Flickr

non goose project by Paul de Valera, on Flickr non goose project by Paul de Valera, on Flickr

non goose project by Paul de Valera, on Flickr non goose project by Paul de Valera, on Flickr

non goose project by Paul de Valera, on Flickr non goose project by Paul de Valera, on Flickr

non goose project by Paul de Valera, on FlickrEnter your email address to join: