You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

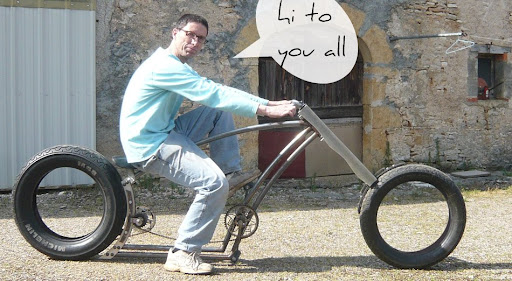

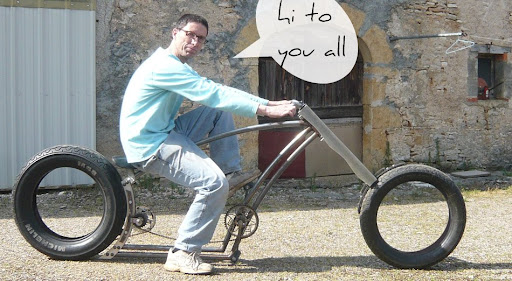

my full hubless project

- Thread starter thdu

- Start date

Help Support Rat Rod Bikes Bicycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

hi,

a little update : the rear wheel drive

i have to join this 2 cogs with a chain through the frame :| :

many complications to find the chain path, no way with the actual frame :? :

I had to redo several parts to arrive there

i make this new one :

and i modify the rear of the frame :

i put the hub on the new part and now, i can choose the path of the chain :

:

but i have not any time to test it and i simply assembled the parts and put the chain to see the result

( now, i show you the 2 side :wink: )

a short video to show the system running :

http://www.youtube.com/watch?v=b-y8p6SK2z8

at the end : view of a possible future :mrgreen:

a little update : the rear wheel drive

i have to join this 2 cogs with a chain through the frame :| :

many complications to find the chain path, no way with the actual frame :? :

I had to redo several parts to arrive there

i make this new one :

and i modify the rear of the frame :

i put the hub on the new part and now, i can choose the path of the chain

but i have not any time to test it and i simply assembled the parts and put the chain to see the result

( now, i show you the 2 side :wink: )

a short video to show the system running :

http://www.youtube.com/watch?v=b-y8p6SK2z8

at the end : view of a possible future :mrgreen:

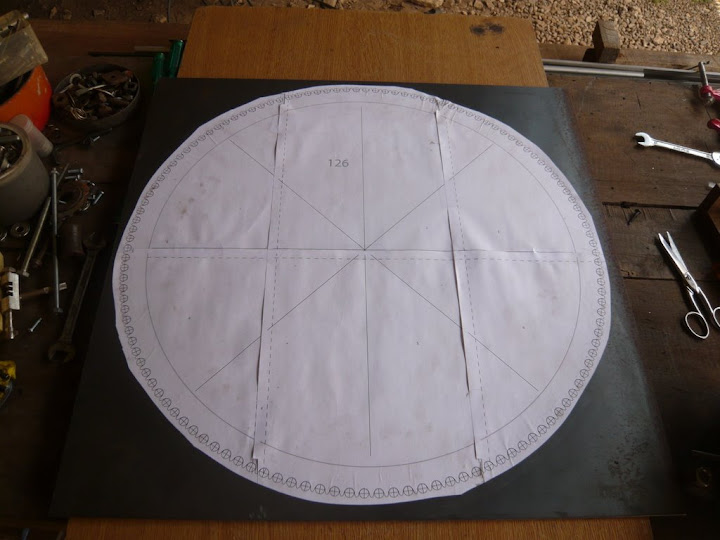

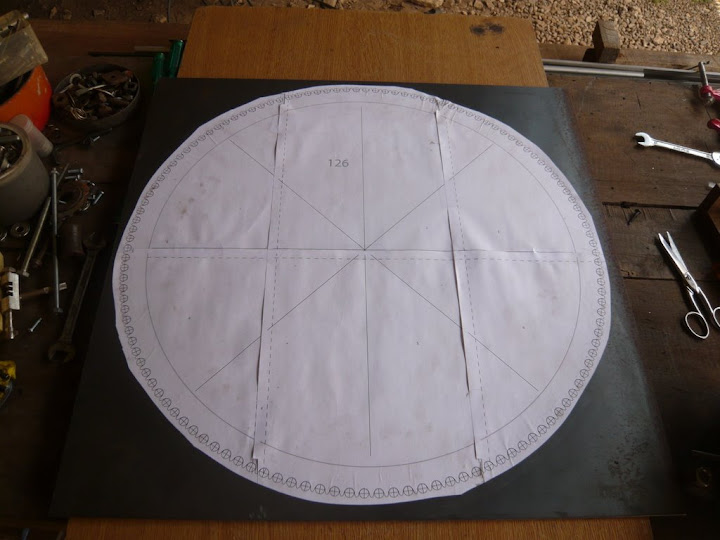

how to get a 126 teeth sprocket :

1, I take a plate

2, I paste a picture

3, I drill lots of holes

4, I cut the circle and I sand

5, I check the functioning

6, I cut it to put into the wheel

7, you have a large sprocket for very few money :mrgreen:

1, I take a plate

2, I paste a picture

3, I drill lots of holes

4, I cut the circle and I sand

5, I check the functioning

6, I cut it to put into the wheel

7, you have a large sprocket for very few money :mrgreen:

Very ambitious and worthwhile endeavor. Extremely impressed!!!!

The motorcycle builder was Billy Lane and he got his Idea from the famous Designer Franco Sabarro.

Franco Sabarro invented the hub-less wheel and it first appeared at the Geneva auto show in 1988 or 1989.

This is straight out of my head, so if you did a google search on it, you will see I am at least close. I may be off by a year.

The motorcycle builder was Billy Lane and he got his Idea from the famous Designer Franco Sabarro.

Franco Sabarro invented the hub-less wheel and it first appeared at the Geneva auto show in 1988 or 1989.

This is straight out of my head, so if you did a google search on it, you will see I am at least close. I may be off by a year.

A possible solution to your problem would be to fill the tire halves with a high density Etheline Vinyl Acetate foam rubber.

There are 3 types of EVA available. Low Medium and high density.

Your solution is within reach!

Here is a link on this wonderful stuff:

http://en.wikipedia.org/wiki/Ethylene-vinyl_acetate

It's pretty hard but does compress. I would form a piece just larger than the inside of your tire and cut "sipes" along the outer surface (the surface next to the inside of the tire) then use vinyl cement ( if you sniff glue you know what this is). This will allow for compression/deflection.

Non pneumatic tires that will still behave like tires.

If you cut a round block out, you could secure it to a powered turn table and literally turn it down with heavy duty sand paper in minutes and then secure it to the insides of the tires. Ultra light stuff cuts really well with a hand saw, but for precision down the middle, you may want to use a vertical band saw.

I would draw a radius template out of that same type of tire when it was inflated. Then use that template and exact radius (of the outside to cram into the insideof the tire). you can turn down your foam with heavy grit sand paper. Literally shove the foam half into the glued tire half. Too much formed foam is better than not enough. Make it fit, trim as needed.

It's basically tennis shoe sole material.

Just an idea.

There are 3 types of EVA available. Low Medium and high density.

Your solution is within reach!

Here is a link on this wonderful stuff:

http://en.wikipedia.org/wiki/Ethylene-vinyl_acetate

It's pretty hard but does compress. I would form a piece just larger than the inside of your tire and cut "sipes" along the outer surface (the surface next to the inside of the tire) then use vinyl cement ( if you sniff glue you know what this is). This will allow for compression/deflection.

Non pneumatic tires that will still behave like tires.

If you cut a round block out, you could secure it to a powered turn table and literally turn it down with heavy duty sand paper in minutes and then secure it to the insides of the tires. Ultra light stuff cuts really well with a hand saw, but for precision down the middle, you may want to use a vertical band saw.

I would draw a radius template out of that same type of tire when it was inflated. Then use that template and exact radius (of the outside to cram into the insideof the tire). you can turn down your foam with heavy grit sand paper. Literally shove the foam half into the glued tire half. Too much formed foam is better than not enough. Make it fit, trim as needed.

It's basically tennis shoe sole material.

Just an idea.

- Joined

- Aug 3, 2010

- Messages

- 12,545

- Reaction score

- 2,885

I'm still not getting how the rims attach to the bike??? :? :?:

He's gonna have to go with a split collar bearing set up. Inside metal portion of the bearing connects to the bike, outside portion connects to the tire. The rims basically take the place of the frame. The bearing set up reinforces the rim.

I would say it's really expensive, but after seeing him come up with that sprocket and seeing his fine fab skills on the rest, this guy can probably make them!

Really cool, man. You have me pondering.

I would say it's really expensive, but after seeing him come up with that sprocket and seeing his fine fab skills on the rest, this guy can probably make them!

Really cool, man. You have me pondering.

This is .......! I 've seen a motorcycle built like this.

:shock: :shock: :shock: :shock: what are you using as a baering inbettween the rim hoop to drive your wheel??? :shock: :shock: :shock: :shock: :shock:

hi, will I wake up this old topic ...

for my bike , i take a little ride of . . . 10 m and i see because of the design ( grrr... i hate design ) of the rear part of the frame ( too close from the tire ) when I pedal, the frame is deformed and touch the tire and that brake ! more I pedal, more that brake :?

and my fork is too complicated and not enough rigid to pilot easily my front wheel :|

the answers : just rebuilt the frame and the fork ! :mrgreen:

Now, changes :

before :

after :

now, the rear frame is more rigid and so, the wheel is easily detachable from the frame

the fork is as simple as possible

i show you the great workshop where I work :mrgreen:

with my friends :wink: :

okay, okay, but perhaps the most important : i can ride it ?

good, then it becomes problematic, between theory and practice, there is a world

again, I put so much time to design and manufacture especially (with the errors, I make several times the same parts) that I have almost never time to test the bike

over my digital camera passed away and it took a disassembly / reassembly for full resurrects :shock:

short videos I've recovered :

entire view of the problem :

:

http://www.youtube.com/watch?v=961q7CpsSe0

me, not very easy :roll:

http://www.youtube.com/watch?v=b9Y8PGdjPDE

and my son who quit his z1000 to ride it

http://www.youtube.com/watch?v=c6V35jeTlZw

for sure, there will be a maximum of adjustments and other development to be done to make this thing riding easily

maybe in 6 month ? 8)

for my bike , i take a little ride of . . . 10 m and i see because of the design ( grrr... i hate design ) of the rear part of the frame ( too close from the tire ) when I pedal, the frame is deformed and touch the tire and that brake ! more I pedal, more that brake :?

and my fork is too complicated and not enough rigid to pilot easily my front wheel :|

the answers : just rebuilt the frame and the fork ! :mrgreen:

Now, changes :

before :

after :

now, the rear frame is more rigid and so, the wheel is easily detachable from the frame

the fork is as simple as possible

i show you the great workshop where I work :mrgreen:

with my friends :wink: :

okay, okay, but perhaps the most important : i can ride it ?

good, then it becomes problematic, between theory and practice, there is a world

again, I put so much time to design and manufacture especially (with the errors, I make several times the same parts) that I have almost never time to test the bike

over my digital camera passed away and it took a disassembly / reassembly for full resurrects :shock:

short videos I've recovered :

entire view of the problem

http://www.youtube.com/watch?v=961q7CpsSe0

me, not very easy :roll:

http://www.youtube.com/watch?v=b9Y8PGdjPDE

and my son who quit his z1000 to ride it

http://www.youtube.com/watch?v=c6V35jeTlZw

for sure, there will be a maximum of adjustments and other development to be done to make this thing riding easily

maybe in 6 month ? 8)