Hi, this is the first real motored build i have done. I tried and failed with a whipper snipper bike and decided if i was going to do it i might as well do it properly. So i pulled an old 5hp Briggs out from down the back of the shed, grabbed a cool frame my uncle had sitting in his garden, and got building. I intend to a torque converter primary belt to jackshaft, then to a transmission sheave on the rear wheel. I have a Honda motorbike carb which i will run in the Briggs for better performance. Hopefully it works...

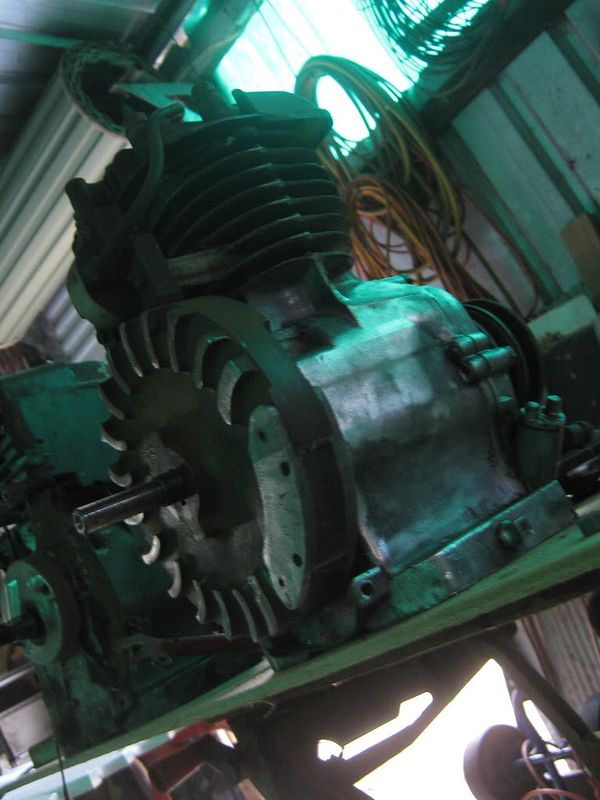

Will hopefully break the fins off this and grind it down, make it purty....

Sturmey Archer coaster hub wheel i scored free

The carby i hope to use.

Engine mock-up.

Engine mounts are tacked on, ill use my uncle gassed MIG to weld them solid as i have a cheapy gasless.

I actually got it centered! :shock:

Well, any tips and stuff will be appreciated, Cheers

Will hopefully break the fins off this and grind it down, make it purty....

Sturmey Archer coaster hub wheel i scored free

The carby i hope to use.

Engine mock-up.

Engine mounts are tacked on, ill use my uncle gassed MIG to weld them solid as i have a cheapy gasless.

I actually got it centered! :shock:

Well, any tips and stuff will be appreciated, Cheers