Thanks Buddy!

I looked at the pic of your springer and went out into the garage to look at Gumby Rumpus for comparison ..... Looks the same to me the way you have it set up. ( only difference is mine was a girls springer [ which I shortened the head tube to fit a Schwinn frame] and yours is a mens ). The only thing I can think of... are the bolts you used on the lower end the ones with a collar? ( which is what you want to use). Mine came complete , I just took it apart , modified , and reassembled mine. rides nice!

Thanks again! Great Build too by the way!

Hope my jibber jabberin helps

I looked at the pic of your springer and went out into the garage to look at Gumby Rumpus for comparison ..... Looks the same to me the way you have it set up. ( only difference is mine was a girls springer [ which I shortened the head tube to fit a Schwinn frame] and yours is a mens ). The only thing I can think of... are the bolts you used on the lower end the ones with a collar? ( which is what you want to use). Mine came complete , I just took it apart , modified , and reassembled mine. rides nice!

Thanks again! Great Build too by the way!

Hope my jibber jabberin helps

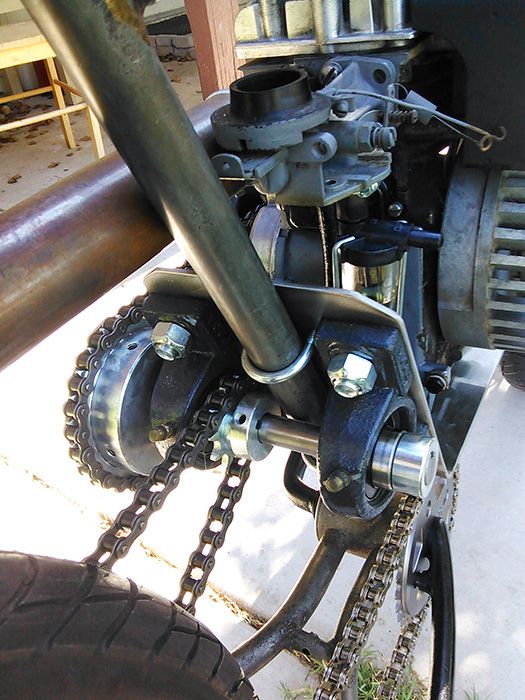

So, I have these columbia springer forks that I am using and I am going with the 24" wheels. I am thinking about duplicating the bottom of these about a inch and a half up from where they are now (where the the wheels bolt on) to shorten. Drill cut grind. I do not see it affecting anything except height. If anyone has done this or knows of a pitfall I am about to step into please let me know.