Re: 1930 Hartford by Westfield Mfg/Pope

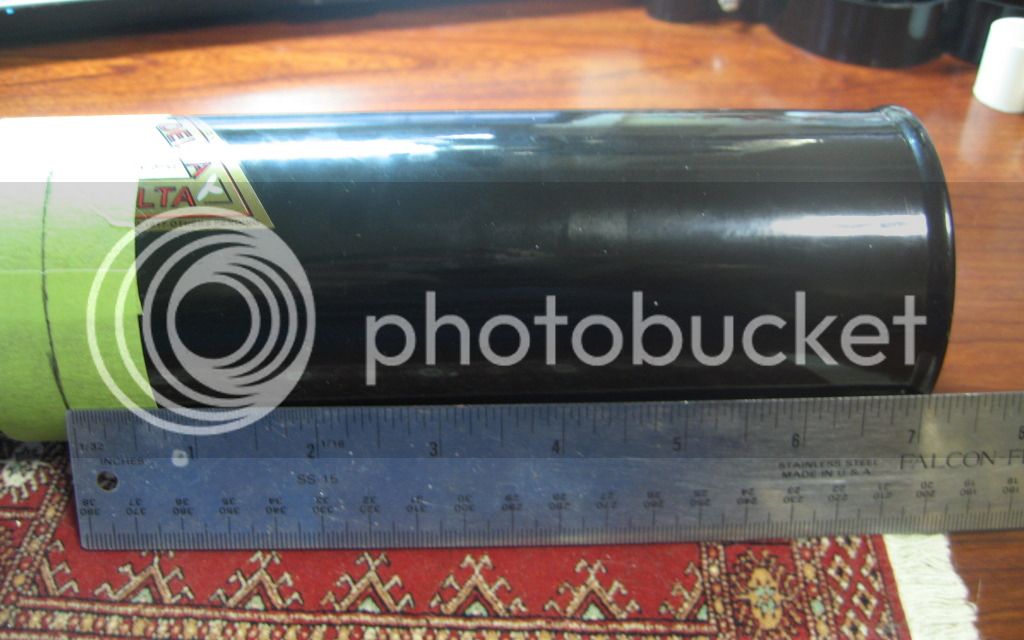

Found the correct original Delta light and battery can yesterday so two missions accomplished!!!!!! These were the last two accessories I needed for this bike to get the bike back exactly as it was before it was parted out and should be in the mail to me this week. Last week I had started fabricating a Delta single cell battery canister from a reproduction double cell canister. I will still complete that project and document it here for anyone wishing to do something similar as these are so hard to find but the original will go on the Hartford.

It's really funny how things show up in spurts as I had looked for these accessories for over a year and found them all over a 3 week period. I looked for the Persons speedo unit for over a year with no luck & now have ended up with parts for three of them in the last 3 weeks. Both the 2 latest had original cables, one had the mounting brackets, and both work so now I have three of these speedometer heads, two cables, and one set of brackets. I'll take the best parts to make the unit for the Hartford. I am going to try to find or fabricate the additional parts to get all three back working. I still need the piece for the wheel & may have to fabricate those parts but all is good as this bike will now have all the original rare accessories back on it.

Not sure what I'll do with the two extra Persons speedos, one may go on my Columbia, and the other one may go up for sale just not sure yet.

Had family commitments all weekend so didn't get any real work done on the bike but it was still a very productive weekend!!!!!!!! Thanks. - Gary

Found the correct original Delta light and battery can yesterday so two missions accomplished!!!!!! These were the last two accessories I needed for this bike to get the bike back exactly as it was before it was parted out and should be in the mail to me this week. Last week I had started fabricating a Delta single cell battery canister from a reproduction double cell canister. I will still complete that project and document it here for anyone wishing to do something similar as these are so hard to find but the original will go on the Hartford.

It's really funny how things show up in spurts as I had looked for these accessories for over a year and found them all over a 3 week period. I looked for the Persons speedo unit for over a year with no luck & now have ended up with parts for three of them in the last 3 weeks. Both the 2 latest had original cables, one had the mounting brackets, and both work so now I have three of these speedometer heads, two cables, and one set of brackets. I'll take the best parts to make the unit for the Hartford. I am going to try to find or fabricate the additional parts to get all three back working. I still need the piece for the wheel & may have to fabricate those parts but all is good as this bike will now have all the original rare accessories back on it.

Not sure what I'll do with the two extra Persons speedos, one may go on my Columbia, and the other one may go up for sale just not sure yet.

Had family commitments all weekend so didn't get any real work done on the bike but it was still a very productive weekend!!!!!!!! Thanks. - Gary